If you are interested in the various components of a mechanical keyboard, it is probably because you have already read the many advantages that this type of keyboard can bring you on a daily basis, and you want to learn more about it.

So we invite you to learn what is in a mechanical keyboard. At the end of this article, you should then know which parts are necessary to build a mechanical keyboard.

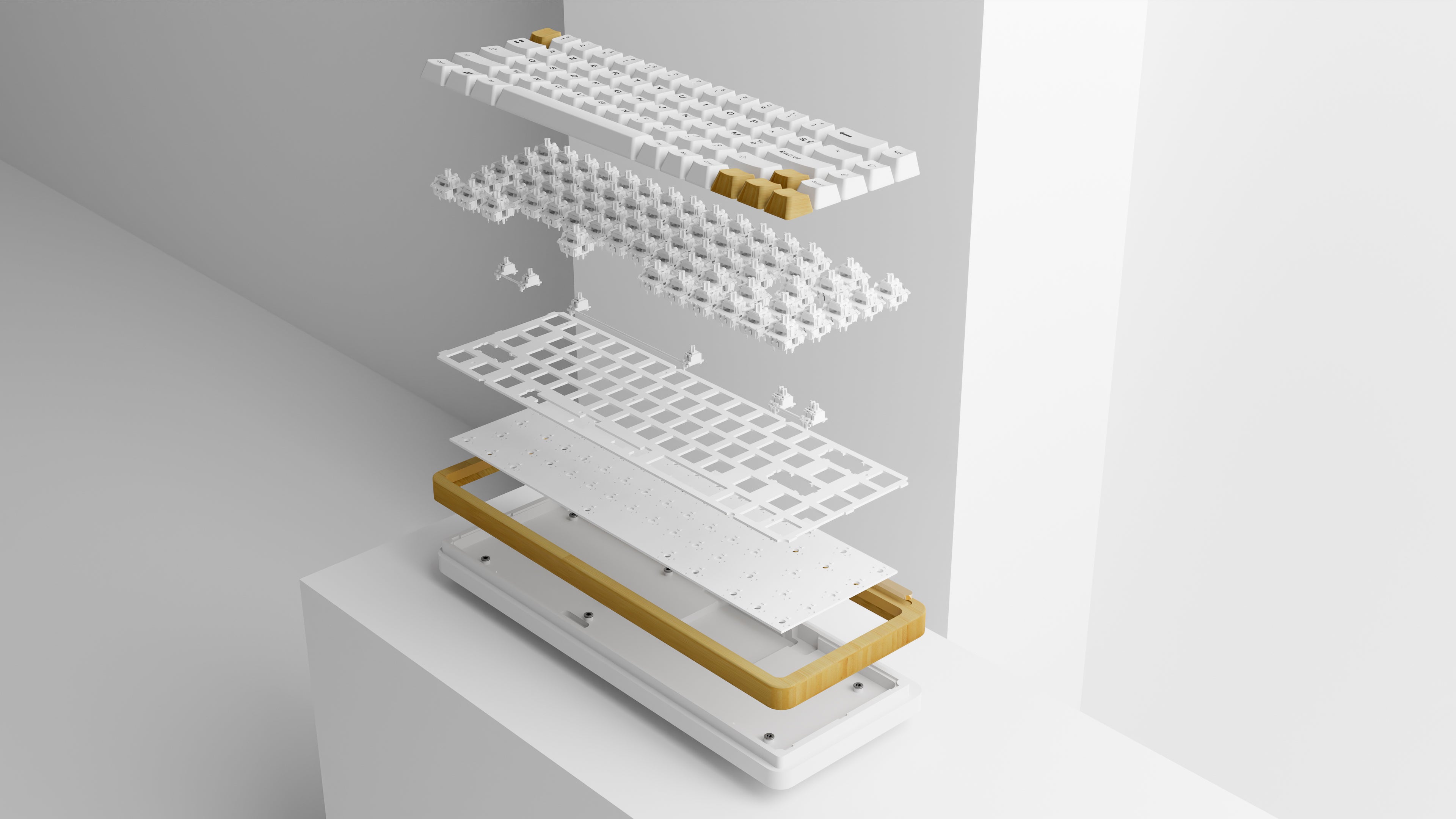

The PCB printed circuit

The printed circuit (or PCB) can be considered to be the brain of a keyboard. The size of your device depends on it, as well as its characteristics. The PCB is placed inside the case. It is he who establishes communication between switches and your computer.

There are 3 main types of PCB: standard, hot interchangeable, and the PCB with a hole in leaving.

- Standard PCB: this is the one used by the majority of mechanical keyboards. On this model, the switches are welded to the PCB. The placement of the keys is very flexible.

- The hot replaceable PCB: here, the switches are not welded, but just to drive into the printed circuit. It is therefore much easier to replace switches on this type of PCB. A hot replaceable print circuit also allows a quick and easy configuration. Most complete but also the most expensive solution, this is particularly the case with high -end keyboards such as the Rhizome Duo.

- PCB to hole crossing: this type of keyboard is not most practical, because you must weld many components, such as resistances, diodes, controller, USB port, etc.

The box

In a mechanical keyboard, the box has the role of maintaining all your components together, and protecting them from the elements. This element can be declined in various materials with different properties. It is therefore up to you to choose the one that suits you best.

The plastic case

The plastic case is most frequently used, since its production is easier to carry out, and is above all less expensive. The option of ABS plastic is the most common. This type of case is delivered with a metal plate for the support of the structure of the case.

However, this material tends to be unstable and not very solid. However, it is suitable for people with a reduced budget and seeking to have a light keyboard.

Aluminum box

The aluminum box has the distinction of being much more robust and rigid. The quality of aluminum used has a great impact on the quality of the case. If you want to have a heavy, solid, aesthetic case and with a very modern look, then the aluminum case would be the option to consider.

The acrylic case

An acrylic case is made from a plastic with the same hardware as a glass. It is therefore a light material, and which has the particularity of letting the light effects pass through the case.

The natural material case

It is possible to find in the market keyboard models made in natural materials, such as bamboo for example. Robust, aesthetic and exotic, this type of keyboard allows you to type in originality, while remaining eco -responsible.

The plaque

The role of the plaque (or "flat") is to maintain the whole in a mechanical keyboard. This structure also improves the construction quality of your keyboard. This plate can be aluminum, carbon fiber, brass, steel, etc. Depending on the material used, the plate can therefore be either flexible or rigid.

A rigid plate makes the installation of the switches easier. On the other hand, a flexible plate offers more flexibility during the strike, which makes the use of the keyboard more pleasant. Finally, a plate can be available in various colors, in order to make your keyboard more aesthetic.

Stabilizers

Stabilizers are essential to your mechanical keyboard, as they prevent large touches from vacillating. By equipping your keyboard with good stabilizers, you can enjoy an optimal strike experience. Several assembly options are available for stabilizers. They can therefore be:

- Mounted on a plate: the stabilizers are fixed to the metal plate above the printed circuit. This is usually the case on prefabricated keyboards, but the typing experience obtained is not optimal.

- Screwed: stabilizers are directly screwed into the PCB. We then obtain a more stable and safer strike experience. This is why this option is the most recommended.

- By Snap-in: Stabilizers start here in the PCB. The feeling is good, but not as pleasant as that provided by stabilizers to screw.

Switches

Switches are most likely the most important elements in a mechanical keyboard. In addition, it is on this component that we find the most options on the market. Depending on the mechanisms used, switches can give very different strike sensations. The different solutions on the market then allow everyone to get a feeling adapted to their needs or tastes.

There are three main types of switches: linear, touch and clicky (or clickable)

- The linear switch: this type of switch has a mechanism that allows you to benefit from a regular, soft and noise strike.

- The tactile switch: this switch has a small notch which opposes a small additional resistance when pressing the button, before yielding. The striking feeling is then more tactile, more mechanical, with a slight vibration.

- The clicky switch: the clicky switch has the same notch as on the touch switch, but also emits a characteristic metallic "click" when pressing the key. The return is therefore both tactile and sound.

You must therefore choose your switch according to your preferences. Switch are generally recognizable by their color: red (red) for linear, brown (brown) switches for touch switches, and blue (Blue) for clicky switches.

The keys

The keys are also available in a wide variety of profiles, designs and materials. Likewise, their price can vary considerably, some kits up to 200 dollars! However, it is possible to find it at much more accessible prices, in much more modest materials, but quite functional.

- The profile: this designates the general shape of the keys capsules. These can either be uniform or carved.

- Design: it is important not to confuse "profile" and "design". The design here refers to the color of the caps. On the market, you will find different colors, different patterns. You will certainly find a design suitable for the rest of your keyboard, and perfectly suited to your tastes.

- The material: in general, the hoods of keys are made of PBT or ABS plastic. PBT is more recommended because it is more sustainable. It is also considered to be a high -end plastic.

- The manufacturing method: we can distinguish some manufacturing methods, including laser engraving, simple shooting, double shot, thermal sublimation, etc.

With so many personalization elements and possibilities, you can therefore make you build a mechanical keyboard perfectly suited to your needs and your taste. You can also find on the market the ideal mechanical keyboard for you, whether it is in a classic style, or resolutely modern, or rather exotic.

What is the felt? Everything about this extraordinary material

Which keyboard to choose to work? Our best detailed advice